Metal Contamination Food Industry

metalcontamination food industry

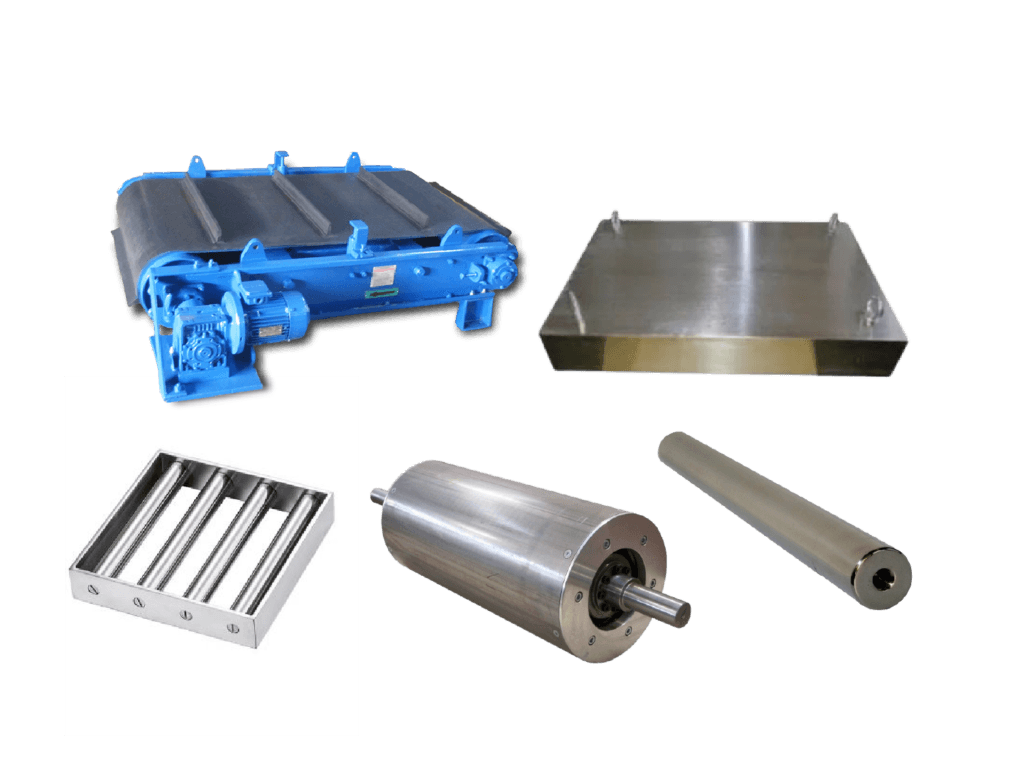

Production facilities are diverse, and so are their challenges. Custom-designed magnetic separation systems offer optimal performance and integration with minimal disruption.

Our Engineering Process

Step 1: Consultation & Site Visit

Step 2: Application-Specific Product Selection

Step 3: Custom Design with CAD Simulation

Step 4: Fabrication & Testing

Customization Features

- Magnetic Strength (6000 to 14000 Gauss)

- Auto-cleaning & manual systems

- Material: SS 304/316 food-grade stainless steel

- Sizes & configurations per product flow

- Compact footprints for retrofitting

Client Case Study

A husk-processing plant needed metal removal without disturbing the husk layer. We designed a 500kg, tractor-towable magnetic sweeper with a self-cleaning system and adjustable height that allowed effective metal separation even through 150mm of husk.

Conclusion

Customized magnetic separators offer precise performance, higher ROI, and seamless integration. Let MagSmith design your next magnetic solution.